Services

Advanced NDT Services

- Tool for rapidly screening long lengths of pipelines from single location.

- LRUT screens pipelines 360° to locate discontinuities for further verification by saving inspection time and cost.

- Combination of multiple wave modes assures about finding longitudinal as well as circumferential discontinuities.

- When low frequency waves (15 kHz to 85 kHz) are propagated from a single location, it can reach up to several meters of distance and inspection data can be captured, interpreted, stored and reported in advanced software.

- Applicable for pipelines with diameters ranging between 2” up to 48”

- Applicable for pipelines with temperature ranging between 0 to 100°C

- Possible to inspect approx. 250 – 300 meters in 1 working day

- Road crossing, river crossing, Dyke, culvert and in-cased pipelines

- Off-shore and jetty pipelines

- In-plant pipelines

- Tank farm and cross-country pipelines

The Short-Range Guided Wave Ultrasonic Technique (SRGUT) is a screening tool designed to test hard to reach areas where inspection area is limited to ~1 meters. The technique is based on the concept of pulsing guided laminar waves into the base material from a transducer placed at the accessible area. The waves propagate up to three feet into the annular plate. When corrosion, pitting, erosion is present the ultrasonic wave mode converts and are received by the same transducer. Short Range Ultrasonic Testing has become a proven and reliable technique as one method for determining the integrity of tank annular plates and under pipe supports where the highest probability of corrosion exists to help prioritize out of service tank maintenance schedule.

Features:

Features:

- Applicable for thicknesses ranging between 6 mm to 16 mm.

- Applicable for pipeline diameters starting from 6”

- Inspections at ambient temperatures.

- Above Ground storage tank annular plates

- Corrosion under pipe supports

- Corrosion at soil air interfaces

- Similar applications with difficult access and area of interest in less than 1 meter.

Corrosion mapping is a scanning method to test surface at small resolution for thickness variations over a larger surface area. It is often found that thickness is recorded at certain intervals and larger area is left un inspected leaving a doubt or fear in operator of missing some hot spots where thickness has reduced. Corrosion mapping is a methodology to perform thickness measurement over entire area to make sure that no such hot spots are missed during testing. Large carbon steel structures such as Above ground storage tanks, vessel, column, underground tanks etc. are prone to corrosion due to various factors hence require routine inspections to prevent any mishap causing serious trouble in production, plant asset and human safety. Using various available corrosion mapping tools, plant owners/Operators can get vital information about plant assets and take corrective action saving huge amounts of production losses.

Features:

Features:

- Thickness range: 4 mm to 150 mm

- Temperature: 0 to 55 deg. C

- Scanning Resolution (min.): 1 mm x 1 mm

- High probability of corrosion detection with up to 0.5 mm

- Highly reliable as output is remaining thickness of steel.

- Helps reduce maintenance costs by minimum use of scaffolding

- 3D data view

- Tank shell plates

- Underground bullet tanks

- Spheres

- Ship hulls

- Pressure Vessel

- Pipeline (minimum diameter 6”)

Pulsed Eddy Current Testing is saving huge amount of money and time for operators while inspecting plant equipment’s or components which are insulated. It is not possible to record remaining thickness on coated, insulated objects; PECT makes it easy by monitoring relative thicknesses through insulation when compared to known reference. This electromagnetic principle-based instrument works on battery and stores inspection data which can be easily converted into tabulated format for reporting purpose.

Features/Advantages:

Features/Advantages:

- No need to remove insulation

- In-service inspection of various Carbon steel structures

- Applicable for objects for diameters starting from 1” up to flat surfaces

- Applicable for objects for thickness ranging between 6 mm up to 100 mm

- Applicable for objects for temperature ranging between -100 to 650° C

- Applicable for objects for insulation/fireproofing thicknesses ranging between 0 – 203 mm.

- Concrete coated skirts and sphere legs

- Insulated Piping, tank, vessel, columns

- Inspections on Al, SS weather jacket/cladding.

- Polymer, metallic mesh, wood, brick etc.

- A powerful ultrasonic testing tool as a replacement of Radiography.

- Fast and recordable UT inspections at site for weld inspection in piping, tanks, vessels etc.

- Applicable on both CS as well as SS.

- Complex geometry inspections are possible.

- Increased probability of defect detection

- Applicable for inspection of boiler tubes, pipelines, pressure vessel welds etc.

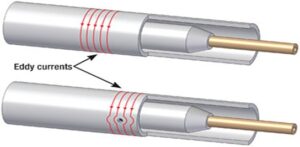

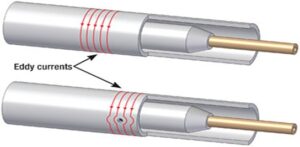

Eddy Current Testing (ECT) – This technique is suitable for detecting and sizing metal discontinuities such as corrosion, erosion, wear, pitting, baffle cuts, wall loss, and cracks in nonferrous materials.

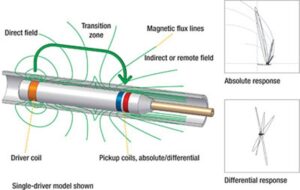

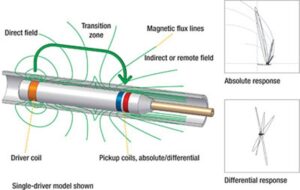

Remote field testing (RFT) – This technique is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferritic stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts. Inspection frequencies ranging from 20 Hz to 250 kHz.

Internal Rotary Inspection System (IRIS) – The ultrasonic IRIS option is used to inspect a wide range of materials, including ferrous, nonferrous, and nonmetallic tubing. This technique detects and sizes wall loss resulting from corrosion, erosion, wear, pitting, cracking, and baffle cuts.

- ECT is used with non‐ferromagnetic metal such as copper, brass, and copper‐nickel alloys.

- Detects: isolated pitting, fretting, cracking, gradual wall loss, erosion, corrosion, through‐wall holes

- ECT can distinguish between ID and OD.

- Outer Diameter Range :0.25” (6.35mm) – 2.5” (63.5mm)

- Wall Thickness Range: 0.020” (0.50mm) – 0.150” (3.81mm)

- Production: 550-700 tubes / 8-hour shift

- Condenser

- Feed water heaters

- Heat exchangers

- Air conditioners

Remote field testing (RFT) – This technique is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferritic stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts. Inspection frequencies ranging from 20 Hz to 250 kHz.

- RFT is used with ferromagnetic metal such as carbon steel.

- Detects: corrosion, erosion, pitting, fretting, wall loss, wear at baffle locations, through‐wall holes.

- RFT can detect ID and OD defects but cannot distinguish between ID and OD.

- Outer Diameter Range: 0.5” (12.7mm) – 3.5” (88.9mm)

- Wall Thickness Range: 0.049” (1.2mm) – 0.250” (6.35mm)

- Production: 350-400 tubes / 8-hour shift

- Boilers

- Feedwater heaters

- Carbon steel tube heat exchangers

- Recovery gas boilers

Internal Rotary Inspection System (IRIS) – The ultrasonic IRIS option is used to inspect a wide range of materials, including ferrous, nonferrous, and nonmetallic tubing. This technique detects and sizes wall loss resulting from corrosion, erosion, wear, pitting, cracking, and baffle cuts.

- IRIS can be used on ferrous or non-ferrous tubes material.

- Detects: accurate wall thickness, pitting, corrosion

- IRIS can distinguish between ID and OD.

- Outer Diameter Range: 0.5” (12.7 mm) – 3” (76.2mm) (OD less than 0.75” (19.05mm) requires special equipment)

- Wall Thickness Range: 0.049” (1.2mm) – 0.500” (12.7mm)

- Production: 250-300 tubes / 8-hour shift

- Heat exchangers

- Air coolers

- Boilers

- Feedwater heaters

- Recovery gas boilers